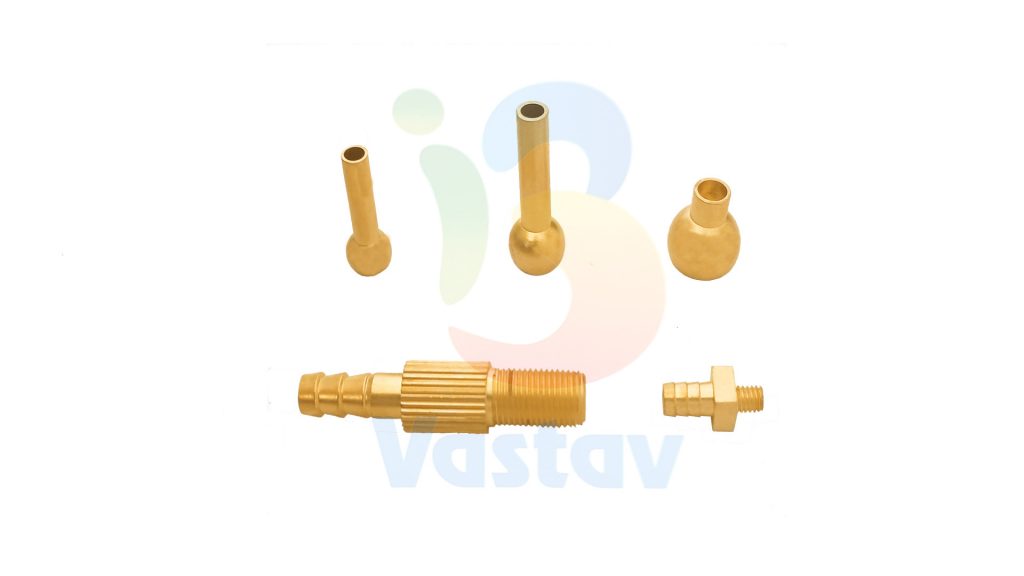

High Quality Brass Nozzle Supplier 1

In industries where precision matters, the choice of components can make all the difference. Brass nozzle supplier, with their versatility and durability, play a vital role in applications ranging from manufacturing to agriculture. This article navigates the landscape of brass nozzle suppliers, shedding light on the factors that make a supplier stand out and why precision is paramount.

Navigating Precision: The World of Brass Nozzle Suppliers

Understanding Brass Nozzles: Precision at the Core

Brass nozzles serve as critical components in various applications, from spray systems to industrial processes. The precision required in their design and manufacturing is central to their effectiveness. A reputable Brass Nozzle Supplier understands this, ensuring that each nozzle is crafted with meticulous attention to detail for optimal performance.

Alloy Expertise: Crafting Durability and Versatility

The alloys used in brass nozzles determine their strength, corrosion resistance, and overall durability. A distinguished Brass Nozzle Supplier possesses expertise in blending copper and zinc to create alloys that withstand harsh conditions. This ensures that the nozzles not only deliver precision in application but also maintain their integrity over time.

Application-Specific Nozzles: Tailoring Solutions for Industries

Different industries have unique requirements when it comes to nozzles. A reliable Brass Nozzle Supplier offers a range of application-specific nozzles, catering to diverse needs. Whether it’s precision spray nozzles for agriculture or high-pressure nozzles for industrial cleaning, customization ensures the perfect fit for every application.

Cutting-Edge Manufacturing: Technology for Precision

Precision in nozzle manufacturing is inseparable from cutting-edge technology. Leading Brass Nozzle Suppliers leverage advanced CNC machining, CAD design, and quality control systems. This technological integration guarantees that each brass nozzle meets the highest standards, providing consistent and reliable performance.

Stringent Quality Control: Ensuring Consistency and Reliability

The journey from raw materials to the final product involves rigorous quality control measures. Reputable suppliers implement stringent inspections at every stage of production. This commitment to quality ensures that each brass nozzle leaving the facility is free from defects, contributing to the longevity and reliability of the component.

Industry Spotlight: Brass Nozzle Suppliers Making a Difference

Explore the industry leaders in the realm of brass nozzle supply. Learn about their innovative solutions, commitment to quality, and the technologies that position them at the forefront of precision nozzle manufacturing.

FAQs About Brass Nozzle Suppliers

What industries commonly use brass nozzles?

Brass nozzles find applications in agriculture, manufacturing, automotive, and various industrial processes. Their versatility makes them suitable for tasks ranging from precision spraying to cooling and cleaning.

Can brass nozzles handle corrosive chemicals?

Yes, brass nozzles can handle a variety of chemicals. However, compatibility depends on the specific alloy used. It’s crucial to consult with the Brass Nozzle Supplier to ensure that the nozzle is resistant to the chemicals in your application.

Do brass nozzles require regular maintenance?

Brass nozzles are relatively low-maintenance. Regular inspections for clogs or wear are advisable, and cleaning with a mild solution helps maintain optimal performance.

Can brass nozzles be used for high-pressure applications?

Yes, brass nozzles are suitable for high-pressure applications. However, it’s essential to select the appropriate design and size based on the specific pressure requirements of your application.

What factors should be considered when choosing a Brass Nozzle Supplier?

Consider factors such as the supplier’s reputation, experience, range of products, customization capabilities, and adherence to industry standards. Additionally, reviews and testimonials can provide insights into the supplier’s reliability.

Are there eco-friendly options for brass nozzles?

Yes, eco-friendly options exist, including designs that minimize water usage or use materials with lower environmental impact. Responsible Brass Nozzle Suppliers often offer such alternatives, contributing to sustainable practices.

Conclusion

Choosing the right Brass Nozzle Supplier is pivotal for ensuring precision, durability, and optimal performance in your applications. From cutting-edge technology to a commitment to quality, the best suppliers embody excellence in the world of brass nozzle manufacturing. As industries evolve, the precision crafted by these suppliers ensures that your processes benefit from the reliability and longevity of brass nozzles.

No Comments